Expo

view channel

view channel

view channel

view channel

view channel

view channel

view channel

RadiographyMRI

Nuclear MedicineGeneral/Advanced ImagingImaging ITIndustry News

Events

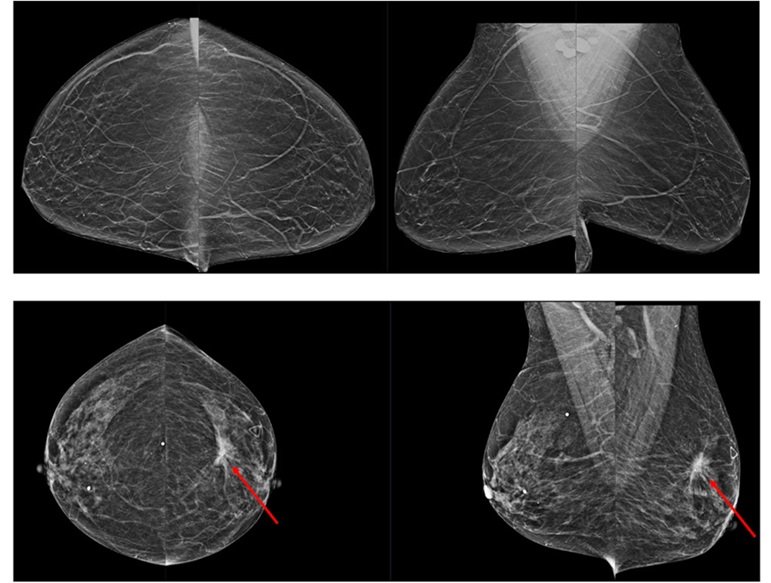

- AI Assistance Improves Breast-Cancer Screening by Reducing False Positives

- AI Could Boost Clinical Adoption of Chest DDR

- 3D Mammography Almost Halves Breast Cancer Incidence between Two Screening Tests

- AI Model Predicts 5-Year Breast Cancer Risk from Mammograms

- Deep Learning Framework Detects Fractures in X-Ray Images With 99% Accuracy

- PET/MRI Improves Diagnostic Accuracy for Prostate Cancer Patients

- Next Generation MR-Guided Focused Ultrasound Ushers In Future of Incisionless Neurosurgery

- Two-Part MRI Scan Detects Prostate Cancer More Quickly without Compromising Diagnostic Quality

- World’s Most Powerful MRI Machine Images Living Brain with Unrivaled Clarity

- New Whole-Body Imaging Technology Makes It Possible to View Inflammation on MRI Scan

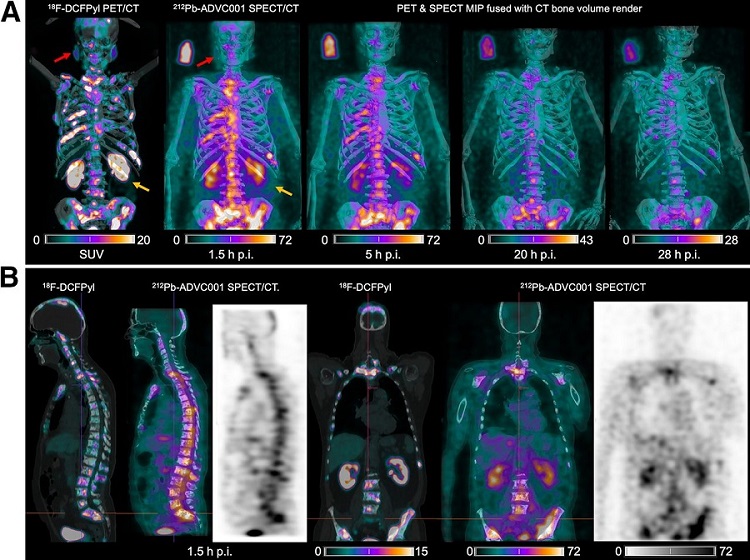

- New Radiotheranostic System Detects and Treats Ovarian Cancer Noninvasively

- AI System Automatically and Reliably Detects Cardiac Amyloidosis Using Scintigraphy Imaging

- Early 30-Minute Dynamic FDG-PET Acquisition Could Halve Lung Scan Times

- New Method for Triggering and Imaging Seizures to Help Guide Epilepsy Surgery

- Radioguided Surgery Accurately Detects and Removes Metastatic Lymph Nodes in Prostate Cancer Patients

- Deep Learning Advances Super-Resolution Ultrasound Imaging

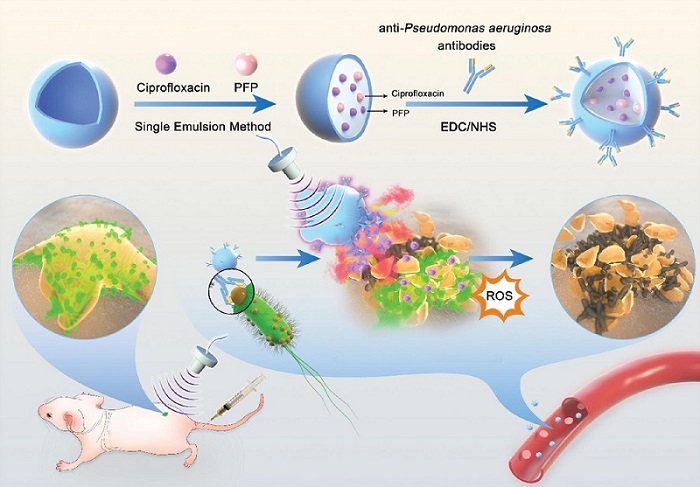

- Novel Ultrasound-Launched Targeted Nanoparticle Eliminates Biofilm and Bacterial Infection

- AI-Guided Ultrasound System Enables Rapid Assessments of DVT

- Focused Ultrasound Technique Gets Quality Assurance Protocol

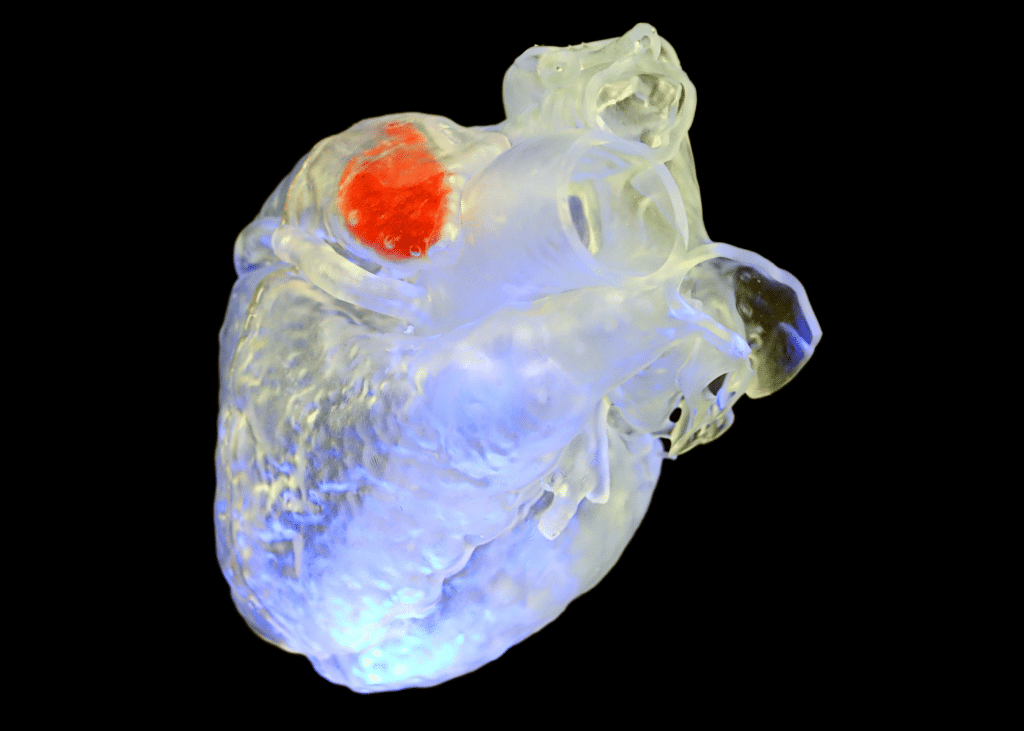

- AI-Guided Handheld Ultrasound System Helps Capture Diagnostic-Quality Cardiac Images

- New AI Method Captures Uncertainty in Medical Images

- CT Coronary Angiography Reduces Need for Invasive Tests to Diagnose Coronary Artery Disease

- Novel Blood Test Could Reduce Need for PET Imaging of Patients with Alzheimer’s

- CT-Based Deep Learning Algorithm Accurately Differentiates Benign From Malignant Vertebral Fractures

- Minimally Invasive Procedure Could Help Patients Avoid Thyroid Surgery

- Global AI in Medical Diagnostics Market to Be Driven by Demand for Image Recognition in Radiology

- AI-Based Mammography Triage Software Helps Dramatically Improve Interpretation Process

- Artificial Intelligence (AI) Program Accurately Predicts Lung Cancer Risk from CT Images

- Image Management Platform Streamlines Treatment Plans

- AI Technology for Detecting Breast Cancer Receives CE Mark Approval

- Samsung and Bracco Enter Into New Diagnostic Ultrasound Technology Agreement

- IBA Acquires Radcal to Expand Medical Imaging Quality Assurance Offering

- International Societies Suggest Key Considerations for AI Radiology Tools

- Samsung's X-Ray Devices to Be Powered by Lunit AI Solutions for Advanced Chest Screening

- Canon Medical and Olympus Collaborate on Endoscopic Ultrasound Systems

Expo

view channel

view channel

view channel

view channel

view channel

view channel

view channel

RadiographyMRI

Nuclear MedicineGeneral/Advanced ImagingImaging ITIndustry News

Events

Advertise with Us

view channel

view channel

view channel

view channel

view channel

view channel

view channel

RadiographyMRI

Nuclear MedicineGeneral/Advanced ImagingImaging ITIndustry News

Events

Advertise with Us

- AI Assistance Improves Breast-Cancer Screening by Reducing False Positives

- AI Could Boost Clinical Adoption of Chest DDR

- 3D Mammography Almost Halves Breast Cancer Incidence between Two Screening Tests

- AI Model Predicts 5-Year Breast Cancer Risk from Mammograms

- Deep Learning Framework Detects Fractures in X-Ray Images With 99% Accuracy

- PET/MRI Improves Diagnostic Accuracy for Prostate Cancer Patients

- Next Generation MR-Guided Focused Ultrasound Ushers In Future of Incisionless Neurosurgery

- Two-Part MRI Scan Detects Prostate Cancer More Quickly without Compromising Diagnostic Quality

- World’s Most Powerful MRI Machine Images Living Brain with Unrivaled Clarity

- New Whole-Body Imaging Technology Makes It Possible to View Inflammation on MRI Scan

- New Radiotheranostic System Detects and Treats Ovarian Cancer Noninvasively

- AI System Automatically and Reliably Detects Cardiac Amyloidosis Using Scintigraphy Imaging

- Early 30-Minute Dynamic FDG-PET Acquisition Could Halve Lung Scan Times

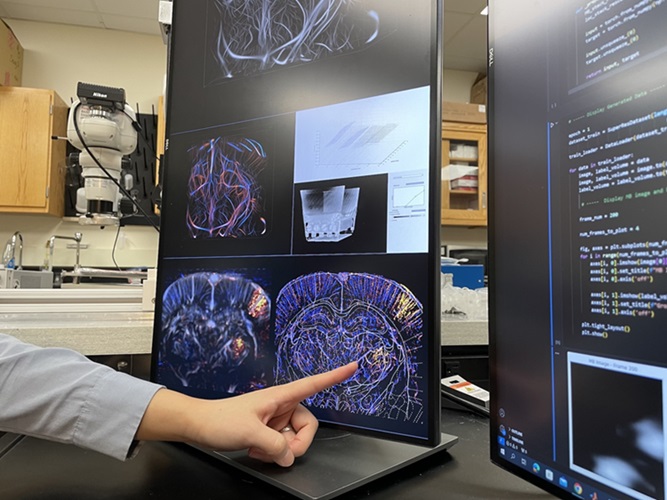

- New Method for Triggering and Imaging Seizures to Help Guide Epilepsy Surgery

- Radioguided Surgery Accurately Detects and Removes Metastatic Lymph Nodes in Prostate Cancer Patients

- Deep Learning Advances Super-Resolution Ultrasound Imaging

- Novel Ultrasound-Launched Targeted Nanoparticle Eliminates Biofilm and Bacterial Infection

- AI-Guided Ultrasound System Enables Rapid Assessments of DVT

- Focused Ultrasound Technique Gets Quality Assurance Protocol

- AI-Guided Handheld Ultrasound System Helps Capture Diagnostic-Quality Cardiac Images

- New AI Method Captures Uncertainty in Medical Images

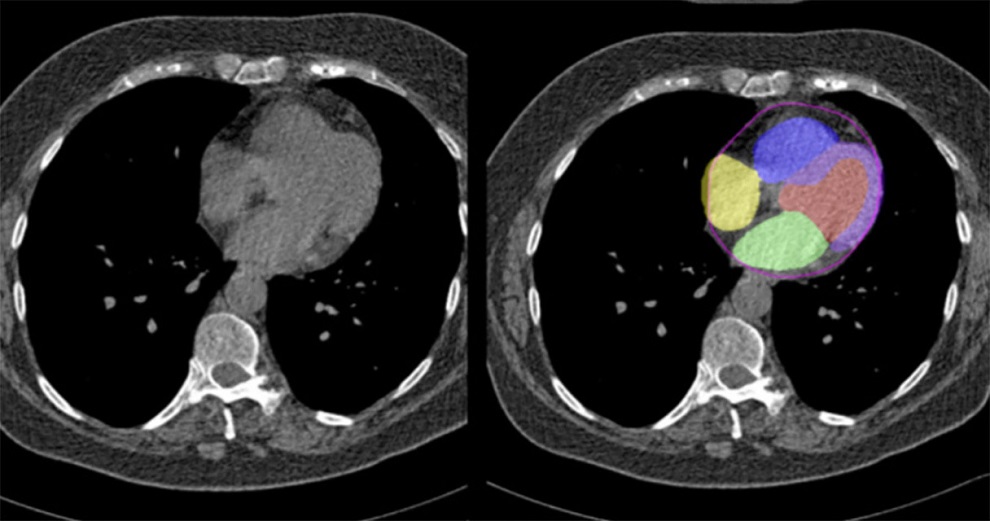

- CT Coronary Angiography Reduces Need for Invasive Tests to Diagnose Coronary Artery Disease

- Novel Blood Test Could Reduce Need for PET Imaging of Patients with Alzheimer’s

- CT-Based Deep Learning Algorithm Accurately Differentiates Benign From Malignant Vertebral Fractures

- Minimally Invasive Procedure Could Help Patients Avoid Thyroid Surgery

- Global AI in Medical Diagnostics Market to Be Driven by Demand for Image Recognition in Radiology

- AI-Based Mammography Triage Software Helps Dramatically Improve Interpretation Process

- Artificial Intelligence (AI) Program Accurately Predicts Lung Cancer Risk from CT Images

- Image Management Platform Streamlines Treatment Plans

- AI Technology for Detecting Breast Cancer Receives CE Mark Approval

- Samsung and Bracco Enter Into New Diagnostic Ultrasound Technology Agreement

- IBA Acquires Radcal to Expand Medical Imaging Quality Assurance Offering

- International Societies Suggest Key Considerations for AI Radiology Tools

- Samsung's X-Ray Devices to Be Powered by Lunit AI Solutions for Advanced Chest Screening

- Canon Medical and Olympus Collaborate on Endoscopic Ultrasound Systems

.jpg)

.jpg)

.jpg)